The Best Worm Drive Circular Saw: 2024 List

Brandon Forder May 5, 2024 9:09 PM

When both power and balance are equally important, experts and experienced DIYers turn to worm drives as their go-to ripping and cutting tool. Worm drives are more expensive and bulkier than standard circular saws, but they save time and effort by making precise cuts in tight quarters. Now you can stop stressing over finding a high-quality worm drive saw. We have researched and assessed all of the best worm drive circular saws on the market in 2022. The products we recommend here are the best of the best because they all use premium components. They have the necessary power to get the job done, and you'll be happy to know that they're lighter than previous models.

Follow this link for a comprehensive analysis if that's the sort of thing that interests you.

Compare Products

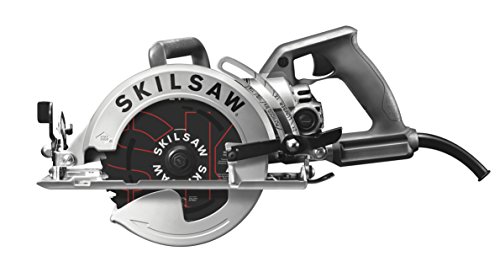

- SCORE9.6

- BrandSkil

- Prime

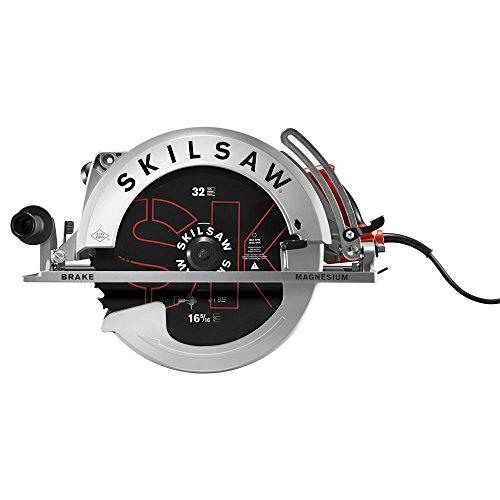

- SCORE9.6

- BrandSkil

- Prime

- SCORE9.6

- BrandSKILSAW

- Prime

- SCORE9.6

- BrandDEWALT

- Prime

- SCORE9.4

- BrandSkil

- Prime

- SCORE9.4

- BrandSkil

- Prime

- SCORE9.2

- BrandMakita

- Prime

Last update on 2024-05-05 / Affiliate links / Images, Product Titles, and Product Highlights from Amazon Product Advertising API

Power capacity

When working with power tools, it is usually preferable to go with a model that has a high power rating. The optimal amperage range for a worm drive saw is between 10-15A.

You should also verify whether or not the worm drive requires a cord. Powerful enough to tackle any job, corded worm drives are preferred over their cordless counterparts.

Motor capacity

In many cases, examining the engine is the only way to accurately estimate the worm drive's power output. The motor is the heart of this device. Worm drive circular saw RPM increases in proportion to motor power. As a result, you should search for circular saws that have a speed range of 4500-5400 RPM.

Durability

The motor's protective housing, the tool's overall construction, the sharpness and ease with which the blades can be replaced all contribute to the worm drive tool's longevity. As opposed to heavier metals like steel, magnesium housings are ideal for worm drive motors due to their balanced design. They can withstand wear and tear better than plastic.

Finally, go for worm saws that have both quick-change blades and carbide-coated blades.

Weight

Pick a worm drive circular saw constructed from aluminum or magnesium to keep the weight down. While the worm drive circular saw will make quick work of cutting through aluminum and magnesium, you should still be prepared to put in some serious back-breaking labor. In addition, because the motor is situated deeper in the base of the worm drive saw, it is typically bulkier than a direct drive circular saw.

The Housing

A compromise between sufficient protection and lighter materials should be sought out, as this design will naturally add weight to begin with. For this purpose, magnesium is frequently selected.

Ergonomics

Be sure the saw's grip is comfortable. You need to find a balance between a comfortable grip and full saw control while setting up the saw's handle. When comparing worm drive saws, it's important to consider whether the added features will be worth the cost.

Blade Changing

It's inconvenient to have to hunt down and find supplementary tools in order to change a blade. In order to save time and effort, you should get a saw that only needs a few tools to change blades.

Blade Left or Blade Right

Whether or not the blade is on the left or right side of the saw is a major factor in choosing the best circular saw. Let me preface this by saying that my viewpoint is biased because I am right-handed. You can simply do the opposite of what I suggest if you happen to be left-handed.

Most circular saws are designed with the blade facing right (a blade right saw). The only benefit of this setup is that the bigger amount of the saw's base shoe may be placed on the work piece with the keeper side of the work piece on the left side of the blade. The problem with this setup is that you have to stoop awkwardly over the saw in order to observe the cut, which can be painful.

A saw with the blade on the left is my favourite since it is easier to observe the line of cut. It goes without saying that being able to see the cut line aids in making a clean cut. The blade on a worm drive circular saw is always on the left, while it is on the right on most sidewinders. You can buy some sidewinders with the blades on the left if you look hard enough.

Cut Depth and Depth Adjustment

Greatest depth of cut indicates the maximum thickness of the material that can be removed from the work piece. When the base shoe is tilted to a right angle, a 7-1/4-inch saw can cut about 2 3/8 inches deep, while a 6-1/4-inch saw can cut about 2 14 inches deep. Cutting 2x12 rafters to stick frame a hip roof isn't something most people do every day, but making bevel cuts, which need an out-of-square saw base, is a common necessity.

Two-by-material at an angle more than 45 degrees can be cut in a single pass with a 7 1/4-inch saw. Saws with a maximum depth of cut of 612 inches at 45 degrees aren't the ideal option if you plan on making a lot of bevel cuts. Smaller trim saws can be helpful for cutting sheet goods like plywood and paneling, but they don't have the power to cut through building materials.

When preparing to make a cut with a circular saw, the blade should be placed about 14" deeper than the wood. The depth of cut on most saws can be adjusted with a sliding mechanism and a locking lever. The most effective circular saws have depth adjustments that can be made quickly and with one hand.

Bevel Capacity and Bevel Adjustment

Cutting with a blade that is at an angle to the work piece is called a bevel cut. The use of bevel cuts allows for the creation of compound angles on rafters and simple miter cuts on trim pieces. All high-quality circular saws have a shoe-tilting capability, however the maximum bevel cut angle can restrict your cutting options. The best circular saws have bevel capacities of at least 45 degrees and up to 53 degrees.

Since the blade is slicing through what amounts to a significantly thicker board when cutting a 45° bevel in 2x material, a lot of power and torque is required. Since worm drive saws have more torque, they are superior to sidewinders, which often struggle to make these kinds of cuts.

For most saws, the bevel angle is adjusted via a lever that locks in place and a sliding mechanism. An easy-to-read scale is essential for a quality circular saw, but positive stops at common angles are a great bonus.

Safety Features

Handheld circular saws simply have handles for protection. They allow you to have a solid grip on the tool and to halt its operation promptly if something goes wrong. There are a lot of ways that things could go wrong, so it's important to keep an eye on your equipment and tighten any bolts that might be slack. Inspect the blade before you put the plug in the tool.

Warranty

The maxim that "the longer, the better" applies here. On the other hand, the standard warranty period offered by manufacturers is between two and three years. It's vital to read the warranty information for each brand before committing to a purchase, as the terms and conditions may vary. It's great if the vendor lets you return the tool within 30 days if it doesn't work as advertised or arrives damaged.

Which is better - worm drives or circular saws?

There are situations in which a worm drive circular saw excels beyond the capabilities of a regular circular saw, and there are others in which the two tools fall short. Worm drives are superior for ripping because they can provide more torque. Also, the worm drive circular saw is easier to maneuver in confined locations. The regular circular saw has the benefits of being less expensive and lighter in weight.

What is the difference between a worm drive and a sidewinder?

Blade and gear placement is the main differentiator between worm drives and sidewinders. The worm drive's gears are at a right angle to the blade's rotation, whereas the sidewinder's are parallel to the rotor. Also, the blades in the worm drive are placed on the left, while those in the sidewinder are on the right.

Who Needs A Worm Drive Saw?

Because of the extra torque they generate, this design of circular saw is worth considering. The worm gear and the wheel it engages can obtain a very high reduction ratio. It means you can exert more force on the blade at the expense of its speed.

The advantages of a worm drive circular saw over a sidewinder model become readily apparent when working with thick timbers or hardwood lumber. A worm drive saw will have an easier time slicing through the wood. The good news is that this saw works just as well as a sidewinder circular saw for slicing through thinner boards and panels.

Who Does Not Need One Of These?

A sidewinder circular saw is a more affordable option if you are a casual DIY homeowner who infrequently conducts woodworking tasks. You can also use a sidewinder to create cuts in wood if you work on tiny projects and use thin boards or panels.

Now that you have all the information you need, go back and evaluate each of the listed resources. When looking to buy a cutting tool, it's best to get one that has as many benefits as possible for your specific cutting needs. If not, you probably won't be pleased. However, you shouldn't always assume that the most expensive option is the best one. Once it's in your possession, use it with caution, and revel in its might, but remember the circular saw safety regulations you learned. I was wondering if you had any experience with it. If so, I'd appreciate hearing about your thoughts and preferences on specific models. If you still have questions after reading this, feel free to post them here. I used a worm drive saw analogy, which I hope was interesting.