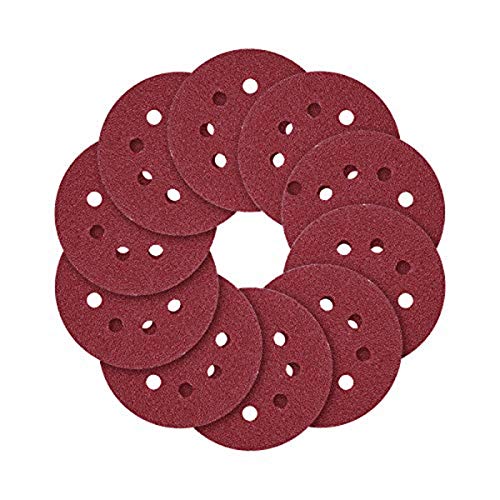

The Best Sanding Discs: 2024 List

Brandon Forder May 6, 2024 7:53 AM

There doesn't appear to be any discernible difference between the various colors of hook-and-loop sanding discs, so how do you determine which ones are the best buy? We know how difficult it is to decide on a sanding disc. However, if you know what you're looking for, the best sanding discs in 2022 can be quite useful tools.

So, chill out! You don't have to be an expert to buy one and put it to use however you see fit. If you need assistance deciding, we're here to guide you in the right direction and provide you the facts you need to make an educated decision that suits your specific requirements.

This shopping guide will help you find the best sanding discs for achieving clean cuts and a flawless final product.

Compare Products

- SCORE10.0

- BrandAwutzut

- Prime

- SCORE9.2

- BrandPOWERTEC

- Prime

Last update on 2024-05-06 / Affiliate links / Images, Product Titles, and Product Highlights from Amazon Product Advertising API

Types of Sanding Discs

The development of abrasive materials has led to an expansion in the variety of sanding discs available. Discs and pads can now be interfaced in a variety of ways, and the backing interface chosen can vary depending on factors including the roughness of the surface being sanded and the amount of pressure used. PSA discs, sticky discs, and hook loop (Velcro-like) sanding discs are the most popular choices. PSA discs have an anti-clog zinc stearate coating to prevent dust buildup and a hole-free construction to minimize the possibility of ripping. A hook-and-loop disc is an abrasive disc that may be attached to a tool by means of tiny plastic hooks and loops. Both methods reliably attach the sanding pad's abrasive to the pad, and either can be easily swapped out when the abrasive wears out or when switching to a different grit. The sanding pad on a hook-and-loop tool may eventually wear out, but there's no need to panic because it's simple to replace.

With the large variety of sanding discs available, from flap discs to floor sanding discs for diverse purposes ranging from finishing and blending to grinding and floor polishing, it can often be challenging to know which disc to choose for every work. Take a look at this guide to common discs and how to play them.

Fiber Discs

They excel at multitasking and may be used for anything from removing bulky stock to blending the top layer of a surface. Fiber discs, which have a heavy-duty coated abrasive disc, can be used with a back-up pad on portable angle grinders for paint and rust removal, deburring, portable grinding, cleaning, and detailing in fields such as collision repair, metal fabrication/welding, and manufacturing/industry.

Flap Discs

Using a right angle grinder and a flap disc—which has abrasive flaps adhered to a hard backing plate—it is possible to simultaneously grind and polish a surface. They're fantastic to utilize for stock and material removal during blending work as well as for beveling, finishing, and cleaning and detailing work. Flap discs are often used in building and construction, auto repair operations, as well as energy and transportation industries.

Paper Discs

Likely the most common and commonly recognized sanding disc, these are classic dry sanding discs used with random orbital and rotary sanders. They are used for mild stock removal to fine finishing on wood, plastic, fiberglass, composite, primer and sealers. A wide variety of grits and PSA and hook & loop attachment options make paper discs a highly flexible tool. Among their many applications are sanding, smoothing, and removing paint. Additionally, paper discs can be used for blending, finishing, and microfinishing in addition to rust and stock removal. The vast majority of businesses, from auto shops to home improvement stores to drywall and paint shops to factories and warehouses rely on them regularly.

Surface Conditioning Discs

Use with disc sanders, bench grinders, pedestal grinders, floorstand grinders, rotary floor buffers, and portable grinders. Perfect for portable and surface grinding, as well as repairing the surfaces of body panels, sanding floors, removing paint, removing parting lines, removing stock, and removing rust. The janitorial industry, the automotive repair business, the energy and environmental markets, the medical field, and the transportation industry all utilize surface conditioning discs regularly. Hook-and-loop, speed-lok/speed-change, and center-mount fasteners all work to secure these adaptable discs.

Dust collection

It's important to note that there are two types of sanding discs that can achieve effective dust collection. With the holes-everywhere designs of the hook-and-loop backing, fine sanding dust may easily reach the vacuum ports of the sander. If you have a severe allergy to dust, these discs could be well worth the additional cost.

Grit readability

If you ever need to check the silicon carbide grit setting on the sander, you can do so by peeling back the cover and reading the markings on the back. Black-on-blue printing is only found on a small fraction of the discs, making the discs with lighter-colored backs easier to read, even if they are not as clean.

Solid foundation

Always check to see if the sanding disk you are purchasing has adequate stability to hold it in place while you work. In fact, this function protects your fingers from the sharp edge of the instrument while also making your workday more enjoyable. Weigh this against your intended use of the machine and its location.

Metal construction

Look for tools that are either wholly metal or that make extensive use of metal. Even though plastic has come a long way, metal is still the gold standard when it comes to durability and sturdiness. You should expect a hefty price increase due to this addition, but the sander will last a very long time as a result.

Size

The scope of the disc will be dependent on the nature of the undertaking. A suitable collection of orbital sandpaper discs is essential for the work at hand and the sander itself.

Grit

The coarseness of the grits on the sanding discs for your wood sander is a measure of their effectiveness. Sandpaper with a grit range of 60–100 is considered medium, while a 40–50 grit disc is considered coarse. The greater the grit number, the finer the sanded surface.

Longevity And Versatility

A sandpaper disc ought to last for a long period and hold up under constant sanding. Also, it needs to be versatile. Our staff recommends a multipurpose sandpaper disc if you plan on using a sander on a surface other than wood.

Composition of Sanding Discs

Natural minerals such as garnet, flint, pumice, and emery were glued to a paper backing to create the earliest sanding discs and abrasive sheets such as sandpaper. Modern abrasive discs are typically produced from synthetic materials like silicon carbide, aluminum oxide, ceramic, and others. Man-made materials provide for greater control over tolerances, sizes, and capabilities which results for higher-quality abrasive discs. These materials can be machined to precise dimensions, keep their abrasive qualities for longer, and tolerate high machining temperatures and pressures without melting.

How do you replace the pad on an orbital sander if the discs keep flying off?

If you change the hook component of your sander, you won't need a new disc. Once you have a replacement disc, you must discard the old one. To prepare the pad for reinstallation, remove the disc and wash it with lacquer thinner. Use a razor blade scraper to remove the little back hoods, and then sand the disc smooth if it still won't come off the backing pad. After wiping down with lacquer thinner, go to a fresh disc sander.

How do I change from sticky discs to hook and loop discs on the disc sander?

PSA sanders can be easily converted to the Velcro hook and loop method. The improved adhesive on the back of these hook and loop conversion discs allows them to adhere to virtually any clean surface. They are available in a range of sizes, from 2 inches to 12 inches. You may start utilizing hook and loop discs right away by setting this simple little gadget on your sander.

What Is The Best Grit For Rough Sanding With An Orbital Sander?

When using an orbital sander for rough sanding, a grit of between 40 and 100 is ideal. In this grit level, painted wood is removed.

All of the information above about sanding discs is reviewed and discussed. Which disc is best? That depends on your needs. As with any other tool, the best sanding disc to use is one that is appropriate for the task at hand.