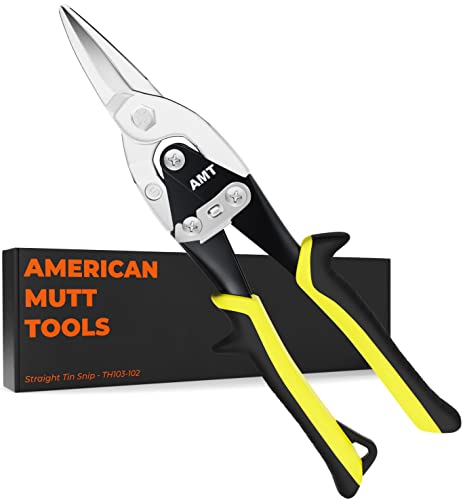

Best Aviation Snips For 2024

Brandon Forder Apr 27, 2024 12:51 AM

Aviation snips are an indispensable tool, and technicians and contractors know this. Anyone looking for a sturdy, user-friendly, and dependable method of slitting or cutting through metal sheets should have one of these on hand. Alternative, less expensive ways exist, but they pale in comparison to the aviation snips' ease of use, strength, and versatility, and inability to cut through very thick metal workpieces. Even if they're tempting, inexpensive, boring variations never offer more than a temporary solution. An aviation snip should be a worthwhile investment that serves you well for many years.

We advise selecting a set with the appropriate characteristics for optimal cutting performance. The sturdy build guarantees long use, and the razor-sharp blade makes short work of any material. The aviation snip also needs to be easy to use since no one wants to wind up with an ugly, jagged edge after hours of battling with thick metal sheets.

Compare Products

- SCORE9.6

- BrandIRWIN

- Prime

- SCORE9.4

- BrandCraftsman

- Prime

- SCORE9.2

- BrandMilwaukee

- Prime

- SCORE9.0

- BrandAmazon Basics

- Prime

- SCORE8.6

- BrandCraftsman

- Prime

Last update on 2024-04-27 / Affiliate links / Images, Product Titles, and Product Highlights from Amazon Product Advertising API

Performance

Because of their adaptability, aviation snips can be used for a wide variety of tasks. Sheet metal can be cut with ease, but they also work great for bending, sculpting, and fitting. When you need to make precise, fast cuts with minimal effort, having a pair on hand is invaluable.

The color coding makes it easy to tell the left and right offsets apart. Left offsets, which are shown in red, are ideal for producing a clean appearance and keeping some fishhooks around the margins of your workpiece. Right offsets are green are for cutting in a clockwise manner whereas straight offsets, as the name suggests, are made for producing straight and small cuts rather than cutting around corners. They are typically orange or yellow.

A well-designed aviation snip is crucial to cutting down on time and energy spent shaping your hair.

Construction Quality

Whether you’re a regular or occasional user of aviation snips, compromising on quality will, in long-run, prove to be a pricey mistake. Professionals recognize the necessity of investing in high-quality instruments that offer value-for-money, which is why they invest solely in strong, tough, and long-lasting solutions.

Those constructed from first-rate materials give top-notch performance and will stay sharper all year long. They are also able to withstand amounts of wear and tear that come with heavy-duty, intense use. Further, have a look at the spring mechanism and if you can select, go for ones boasting an all-tempered steel structure as they are better suited to handle demanding tasks.

Ease of Use

Those that value time, precision, and least exertion in their cutting projects place a high value on convenience. Models with ergonomic, nonslip handles make it possible to work for long periods of time without the user's hands getting tired or cramped.

Each type of offset — left, right, and straight — has its own hue. The user can quickly and easily tell them apart and grab the right component thanks to the thoughtful layout. As an added bonus, their portability and small size make them ideal for working in confined areas.

Blade Quality

The blades at the end of an aviation snip do all of the cutting. The snip's ability to cut through various materials is entirely attributable to the blades' construction. Cutlery blades come in a wide variety, each optimized for a specific metal's hardness and thickness.

Not only do serrated and smooth blades serve different functions, but there is also a noticeable visual distinction between the two. If you want to make quick work of your cutting tasks, use the right kind of blade.

Cutting Direction

When cutting metal, the cutting direction is critical for producing the desired cut shape. The raw material is quite expensive, therefore any mistakes in the cutting process would completely waste it.

Specialized snips are required for many different kinds of cuts, such as angled and curved ones. Both right- and left-handed versions of these snips are available, with yellow, green, and red handles to distinguish between them. Using a straight cut snip is the best option if you merely need to slice through the material without deviating from a straight line.

Weight and size of the snip

This is another important consideration when utilizing the aviation snip on various metals. When cutting metal with an aviation snip, you need to maintain a delicate balance between the tool and the material you're working on.

Using a heavier choice demands you to keep both hands on the tool at all times, making it more cumbersome to work with. To minimize time spent cutting, choose a tool that is proportionately large, such as an aviation snip. While the larger tool may be convenient in some situations, it will not allow you to work with the same precision as a smaller, more portable tool.

Material

Think about the materials you typically work with while deciding on a pair of tin snips. Tin snips can be used to cut various gauges of metal, so it's important to keep that in mind if you plan on cutting anything with them. If you only have 10-gauge steel, it's worthless to have snips that can cut 20-gauge steel. Remember that a bigger metal gauge number indicates a thinner metal.

Besides tin, leather, cardboard, aluminum, copper, vinyl siding, and wire mesh can all benefit from the use of certain tin snips. Tin snips can be used for a variety of purposes, so before purchasing a pair, it's a good idea to double-check the manufacturer's suggestions.

Application

You should know what you'll be using the tin snips for and how sturdy the snips ought to be before you buy them. Tin snips are commonly used for cutting thin gauge sheet metal for home improvement projects like repairing HVAC ductwork and installing new drain pipes. You need a device designed for this purpose if you want to use snips for applications in which you need to cut through a specific thickness of material.

Serrated tin snips are ideal for use with particularly smooth metals because the serrated edges grasp the metal as you cut, preventing the snips from slipping while you work.

Comfort and Grip

Cutting sheet metal by hand can tire your hands out if you aren't using tin snips with a grip that fits your hand size and shape and is designed for your dominant hand. Tin snips come in both right- and left-handed varieties, but offset snips are often designed for the former. A left-handed user would need to switch the snips around such that the clockwise snips would make counterclockwise cuts and the counterclockwise snips would make clockwise cuts.

To protect your hand and reduce the shock of cutting through heavy metal wire and sheet metal, the grip should be constructed of a padded or rubberized material. Finger indents on the handle of some tin snips are designed to improve the user's grip on the tool.

What are some of the precautionary measures to take when using these snips?

Security is, of course, the top priority. Gloves are a must for handling unfinished materials with sharp edges, and safety glasses are essential for preventing eye damage from flying particles and debris.

What is the difference between left, right and straight offsets?

Straight offsets are used for precise, straight cuts, whereas left and right offsets are used for anti-clockwise and clockwise slicing, respectively.

Why are tin snips colored?

Color-coding on the handles of some tin snips designates them for either clockwise or counterclockwise cutting, or for making straight cuts. Snips with yellow handles are for making straight cuts, whereas those with green handles are for cutting in a clockwise direction.

How do you use tin snips?

Tin snips are used in the same way as regular scissors, except the resistance encountered when cutting metal is significantly higher than that encountered when cutting paper. Tin snips should be opened as wide as possible before each cut is made to ensure that the metal is firmly lodged in the cutters. The right amount of force should be applied to make clean cuts.

A straight blade screwdriver or similar piercing instrument is useful for making a pilot hole through the metal before using tin snips to create a circular cut.

An aviation snip is as essential to the toolkit of every builder, technician, or hobbyist as a hammer or screwdriver. They save considerable effort and time as compared to conventional methods of cutting through thick sheets of metal.

The combination of ergonomic, nonslip handles with sharp, durable blades makes premium versions undeniably powerful. You'll find these and more useful functions in our top picks, which will complement your current collection of tools wonderfully.