Best Framing Square : Review And Buying Guide

Brandon Forder Apr 19, 2024 8:18 AM

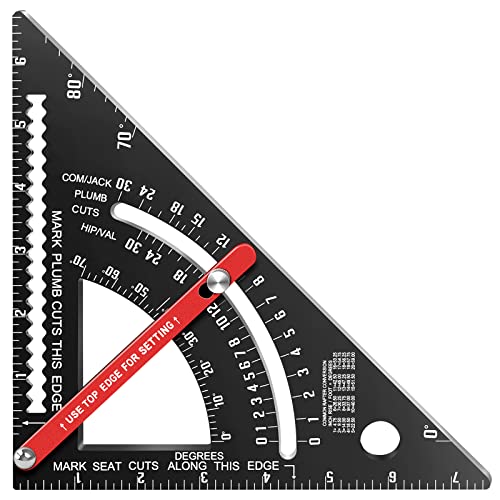

As professionals, we understand the significance of precise measurements in the design and building process. Mistakes in measurement might lead to a costly and time-consuming rebuilding of the entire structure. Therefore, a framing square is favored by architects, carpenters, and civil engineers to eliminate the potential for errors of this nature. Accurate measurements for a wide range of projects require framing squares with flawless gradations. At first look, these hand tools may seem complicated to use, but you'll quickly discover that they are indispensable to your design work. However, with so many options on the market, finding the ideal framing square can be challenging. We've compiled a list of the top framing squares expected to be released in 2022 and written a buyer's guide to assist you select the perfect one.

Compare Products

- SCORE9.4

- BrandIrwin Tools

- Prime

- SCORE9.4

- BrandIrwin Tools

- Prime

- SCORE9.2

- BrandBELA DOMO

- Prime

- SCORE9.2

- BrandStarrett

- SCORE9.0

- BrandJohnson

- SCORE8.6

- BrandSwanson Tool Co., Inc

- Prime

Last update on 2024-04-19 / Affiliate links / Images, Product Titles, and Product Highlights from Amazon Product Advertising API

Intended purpose

The primary factor to think about is the purpose of the framing square. Look for a model with a high build quality if you want an accurate and long-lasting tool. Choose a model with large graduations if you require something that is simple to read and measure.

Build material

You can tell a lot about a framing square's durability and precision from the stuff it's made of. Excellent framing squares are typically made from stainless steel, carbon steel, or aluminum. If you choose a stainless steel tool, though, you'll need to take special care to prevent it from rusting or oxidizing.

Accuracy

Most importantly, when choosing a framing square, accuracy should be your top priority. Incorrect measurements and other problems can arise from using a tool with a lack of precision. Line up the frame square with a ruler and compare the two to see whether it is accurate. If they are parallel, then you can use the square to determine if a line is straight.

Readability

A framing square is useless if you can't make out the gradation lines on it. An easily readable frame square is essential for error-free work. Most manufacturers use a stamp or a laser to permanently mark the increments on the framing squares. It is important that the marks on a frame square be easily visible, hence they should be a different color than the square itself.

Durability

The durability of a framing square is crucial, as it would be a useless tool otherwise. Framing squares' longevity is determined by their construction material and the gradation marks. The inability of the material to withstand stress without cracking or buckling will result in inaccurate readings. And if the markings on the scale fade after a few months, it's useless.

Graduations reflect on your measurements

Squares' scales have graduations, which are the spaces between the various measurements. Each scale has its own unique set of graduations that define the level of detail in your final product. Carpenters tend to use the 1/8-inch graduation since it is the most practical. On the other hand, there are alternatives that provide even more accuracy, such as 1/10 inch, 1/12 inch, and so on.

Tables and conversions ease up calculations

It is extremely irritating when calculations in the middle of a job cause delay and frustration. Keep the ball flowing by reducing the amount of time it takes to find solutions to problems involving complex calculations, conversions, and tables over a granular surface. In any framing square, the engravings of the Essex board and rafter tables are indispensable.

Body and tongue’s scale outlook

Your work's specifics dictate the length of the body and tongue of an L-square. A beginner, however, must appreciate the significance of arm physiques in determining the accuracy of a square ruler. Despite their pinpoint accuracy, thinner scale blades are easily dislodged by even moderate force. However, blades that are thicker tend to stay put and keep a decent level of precision.

How can I know the measurement system of a framing square?

A framing square's description box will tell you what system of measurement it uses. Conversion tables are a handy addition to any calculator, so make sure you know if yours comes with them.

Can I use a framing square as a saw guide?

If the frame square has a sliding ruler that can be adjusted, then it can be used as a saw guide. If you use this feature, the blade will be locked in place, allowing you to make clean cuts without having to readjust the ruler multiple times.

What are tapered framing squares like?

A square with a tapered corner is a classic framing choice. Once upon a time, frame squares were overall thicker, with mills on the edges and sometimes even removable fences. Square rulers wouldn't get lost so easily with this design, and they're still useful and accurate today.

Are framing squares trustworthy for squaring?

Yes! Arms on a framing square are always 90 degrees to guarantee a squared off picture. If you're working on a larger board or wall, though, a square ruler's arms will only be able to stretch so far. When its reach exceeds its ability to help, it becomes useless.

How to use a framing square to calculate roof pitch?

Framing squares are used by carpenters to ensure accurate angle measurements when constructing rafters and stairs. The angle of a roof can be determined with it.

The framing square's handle is placed against one point of the roofline, and the framing square is extended or folded until it hits a second point on a corresponding area of the roof, allowing the roof pitch to be calculated. The location of the second section can be read off based on whether the framing square was extended or folded. For arc measures, for instance, if you started by measuring along an extension side from a corner, you will need to rotate your reading 180 degrees.

Because the readings are presented as "rise over run" rather than degrees, a roof with a rise of 12 inches for every 12 inches of run (a "12/12" roof) would have a value of 1.0. The reading for a roof with a 6/12 pitch would be 0.5, and so on.

How to cut a 22.5 angle with a framing square?

To begin, using the framing square, measure and mark off a 22.5-degree angle on the board.

When using a hand saw to cut following the guidelines, you should angle the saw at exactly 22.5 degrees with the top edge of the board.

Third, use your speed square to ensure that the line is 90 degrees from both the top and bottom of the wood.

The fourth step is to use the jigsaw to follow the marks you made to make an angle of exactly 22.5 degrees. Use 120 grit sandpaper to smooth off any rough patches left over from the cutting procedure.

The fifth step is to apply wood stain if you so desire, and then let it cure for the night.

Finally, drill a pilot hole in the middle of your 22.5 angles so that the screw that secures your hook or hanger sits flush with the back of the board. If you need to use screws, make sure to drill pilot holes that are smaller in diameter, and use wood putty to patch any holes you may find before staining.

A framing square is a tool used by aspiring architects and other designers to take precise measures and create clean cuts. The best frame squares, as determined by widespread consensus and compliance with industry standards, are listed below. We believe this information will be useful in selecting the best framing square for you.